ASE and WrenchWay Join Forces to Promote School Assist

ASE and WrenchWay are working together to grow School Assist as the go-to solution for connecting shops, dealerships, and OEMs with schools. By working together, schools gain classroom resources to better educate students while industry partners build a workforce pipeline of the future for the transportation industry.

How Can WrenchWay Help?

Inside Look at Free Solutions for Schools

WrenchWay’s Free Resources for Schools

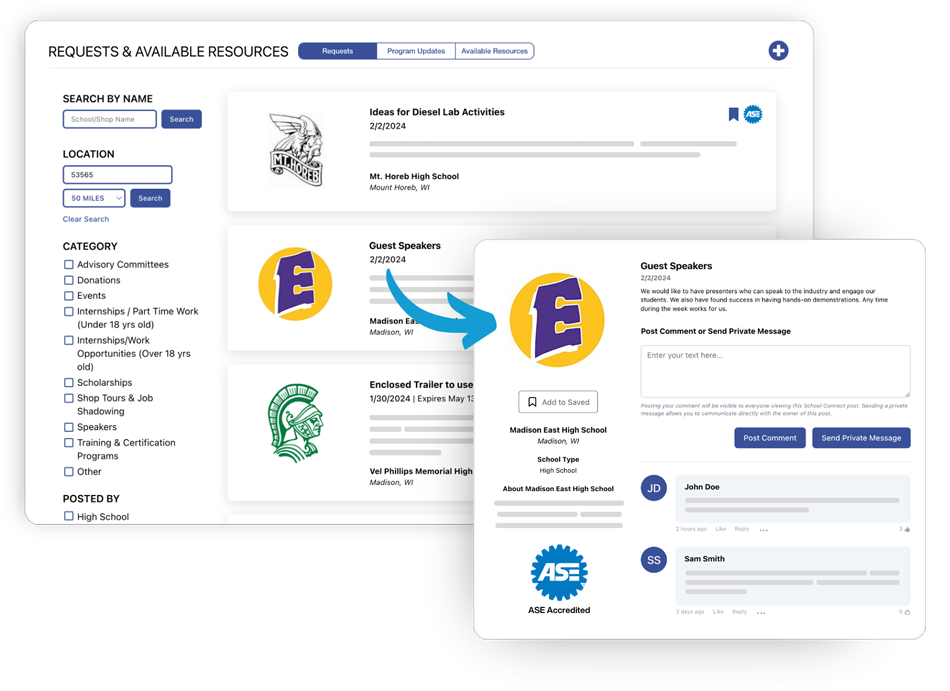

School Assist By WrenchWay & ASE

Build relationships with local shops and dealerships, and get the resources you need to attract students to technician programs and educate them about the industry. Even if your school doesn’t have an official automotive or diesel program, this can be a great tool to help give students exposure to these industries.

Browse available resources from shops and dealerships in your area and post requests for things like:

- Tool and equipment donations

- Advisory committee members

- Shop tours

- Speakers

- Internships/Apprenticeships/Job shadowing

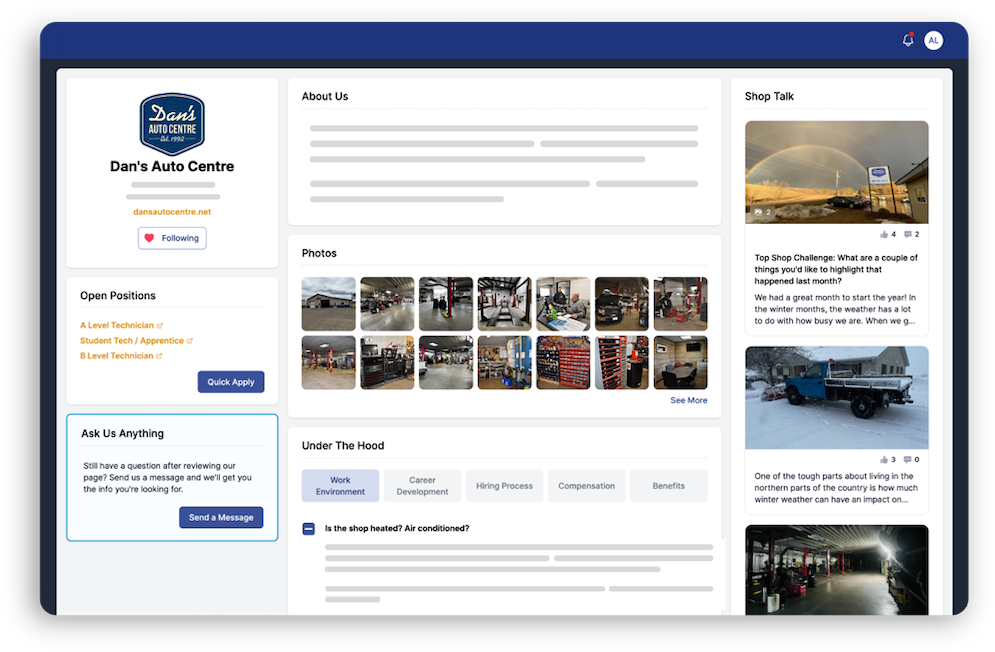

Top Shop Pages

Show your students what it’s like working in the best shops and dealerships in your area. This can also be a great tool to show parents. Top Shop pages include information on:

- Compensation ranges for all levels and detailed benefits coverage

- Photos of the service area and equipment

- Videos of technicians and managers

- FAQs on work environment, career development, and hiring process

- Open position and quick apply

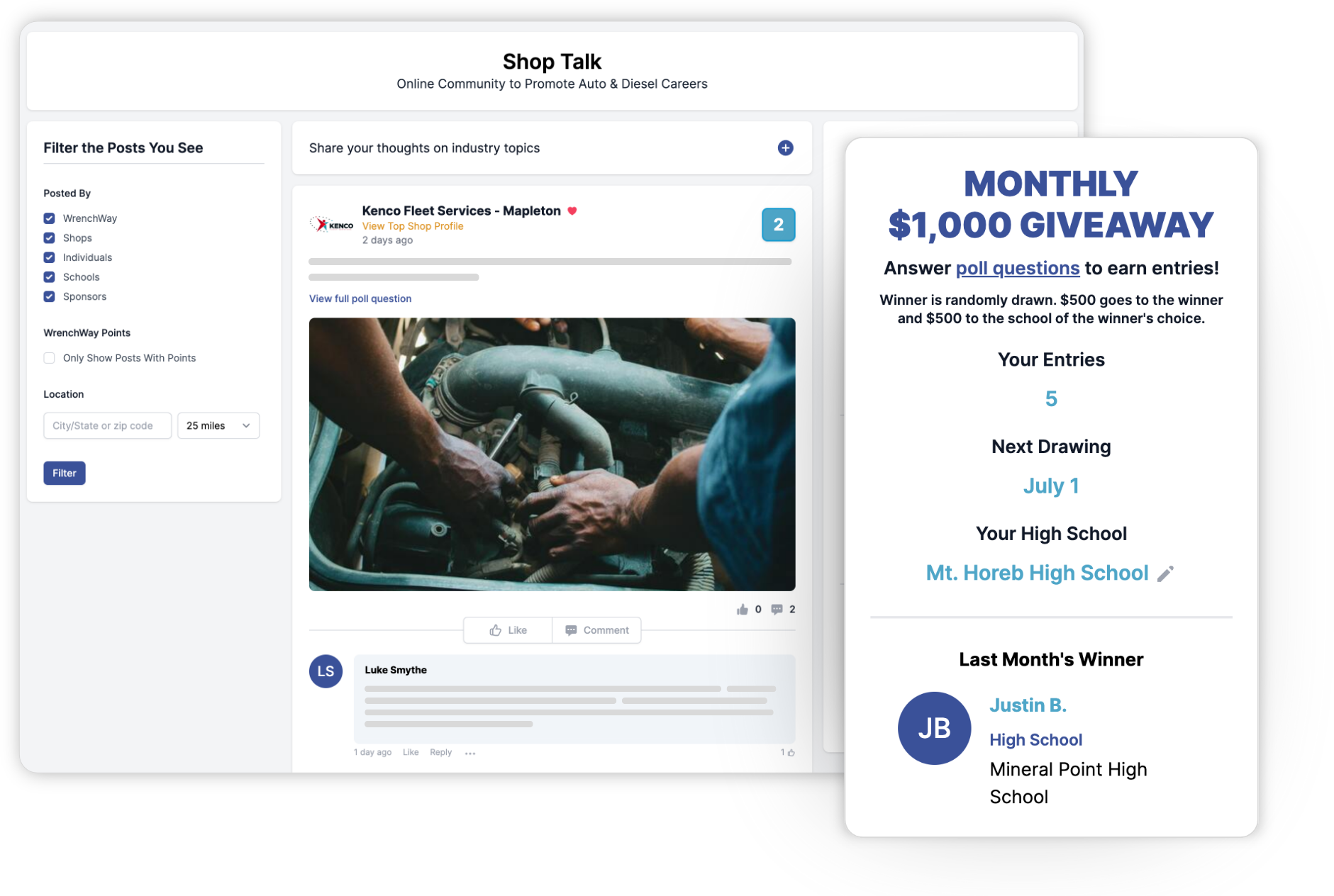

$500 Monthly Giveaways *For High Schools Only*

Every month, one lucky winner gets $500 and then they get to choose a local high school to receive an additional $500. Here’s how it works:

- All high schools signed up for a free WrenchWay Schools account are automatically entered.

- Each week, we post poll questions seeking feedback from technicians, students, and industry professionals.

- Everyone who answers the questions earns entries in our monthly drawing.

- The winner gets $500 and chooses a school to receive the other $500.

- Increase your chances of winning by encouraging your students, staff, and alumni to sign up for a free WrenchWay account.

Why Schools Love School Assist

Hear What Schools Are Saying

Have Questions About School Assist?

Fill out the form below, and someone will be in touch shortly.